Welcome to Foshan Solutions-Pack Co Site

- Favorites

- Help

Welcome to Foshan Solutions-Pack Co Site

Application: Automatic Liquid Piston Filling Machine is designed for the automatic filling of liquid with certain or high-viscosity, such as oil, hand sanitizer, cream, sauce, honey, ketchup, etc. The machine is mainly used in the chemical, food, and pharmaceutical industries. Liquid Filling Machine has a lot of advantages, all parts are made by CNC precision machining, the whole machine uses high-quality stainless steel as the manufacturing material, the main electrical parts of the machine were imported, controlled by PLC, operated by touch screen, high precision almost no need for maintenance, just simple maintenance.

Details:

-Users can choose from 2 to 16 filling heads.

-Pneumatic control system selected brand parts to ensure the performance of durable stability.

-Drip-proof filling head design.

-The filling volume can be adjusted by touching the screen and shaking the lever.

-Frequency control, no bottle no filling.

-Using the upper type liquid cylinder, when the liquid in the cylinder is insufficient, it can automatically alarm and complete the liquid supply automatically.

Automatic Liquid Piston Filling Machine is designed for the automatic filling of liquid with certain or high-viscosity, such as oil, hand sanitizer, cream, sauce, honey, ketchup, etc. The machine is mainly used in the chemical, food, and pharmaceutical industries. Liquid Filling Machine has a lot of advantages, all parts are made by CNC precision machining, the whole machine uses high-quality stainless steel as the manufacturing material, the main electrical parts of the machine were imported, controlled by PLC, operated by touch screen, high precision almost no need for maintenance, just simple maintenance.

Bottle types

Nozzles | 2 | 4 | 6 | 8 | 10 | 12 |

Range (ml) | 30ml – 5000ml | |||||

Capacity (b/min) | 800 – 1000 | 1500 – 1800 | 1800 – 2500 | 2500 – 3000 | 3000 – 3600 | 3600 – 4200 |

Air Comsuption (m³/min) | 1.2 | 1.2 | 1.2 | 1.2 | 1.4 | 1.4 |

Accuracy | ± 0.1% ~ 0.4% | |||||

Voltage & Power | 2000w 220v 50hz/60hz Single Phase, 2000w 380v 50hz/60hz Three Phase | |||||

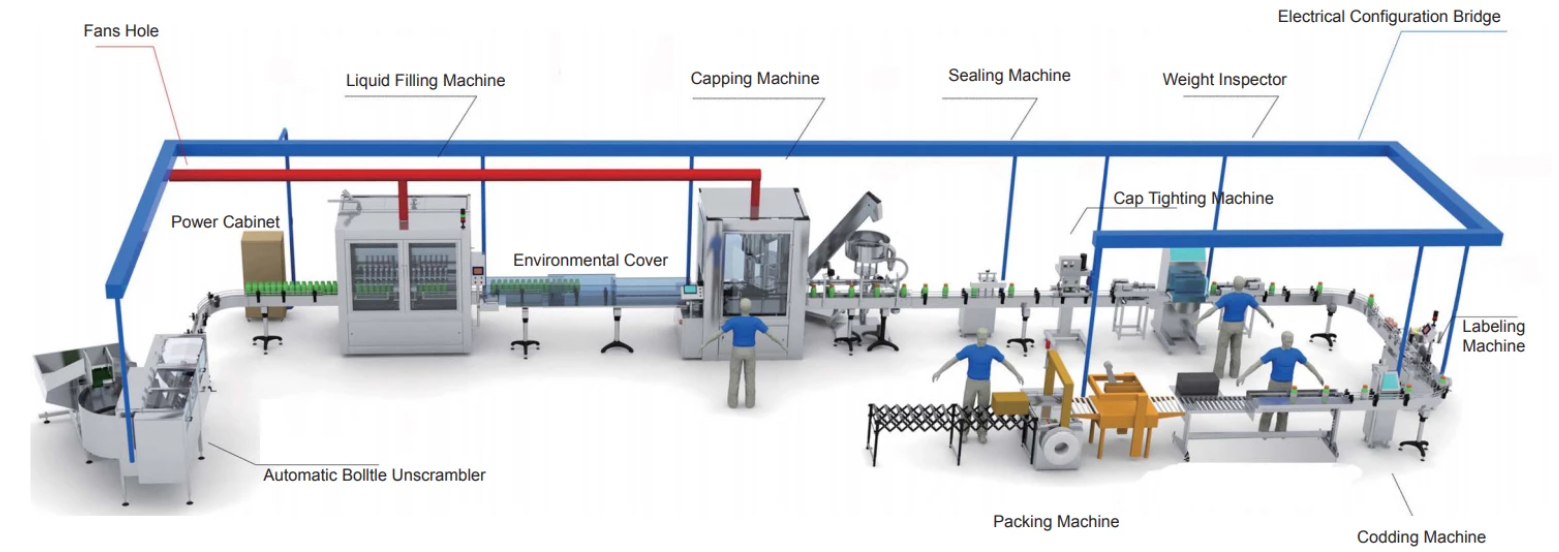

Bottle line

By combining Linear Capping Machine and Bottle Labeling Machine, a highly automated Bottle Line can be formed.